The eccentric presses are a type of machine pressing, mechanically driven, which are used for jobs that require a short run, as in punching and stamping.

In Die Center we tell you all details What you need to know about eccentric presses.

Types of eccentric presses

This type of mechanical press is usually used mainly for the sheet metal stamping, specifically for shape and cut them. To carry out these functions, it makes use of two of its elements, on the one hand, the awl, which serves to give shape, and on the other is the matrix, which is used to cut.

In addition, the eccentric presses They are characterized and differentiated from the others by their high operating speed. Therefore, they are in great demand in the metallurgical sector, since with them small pieces can be made very quickly.

As for the types of eccentric presses, is generally distinguished between: presses a column and presses double column, although a distinction can also be made between:

- Fixed stroke presses.

- Adjustable stroke presses: the stroke can be adjusted by means of two eccentrics which, in turn, can be adjusted to each other.

How the eccentric press works

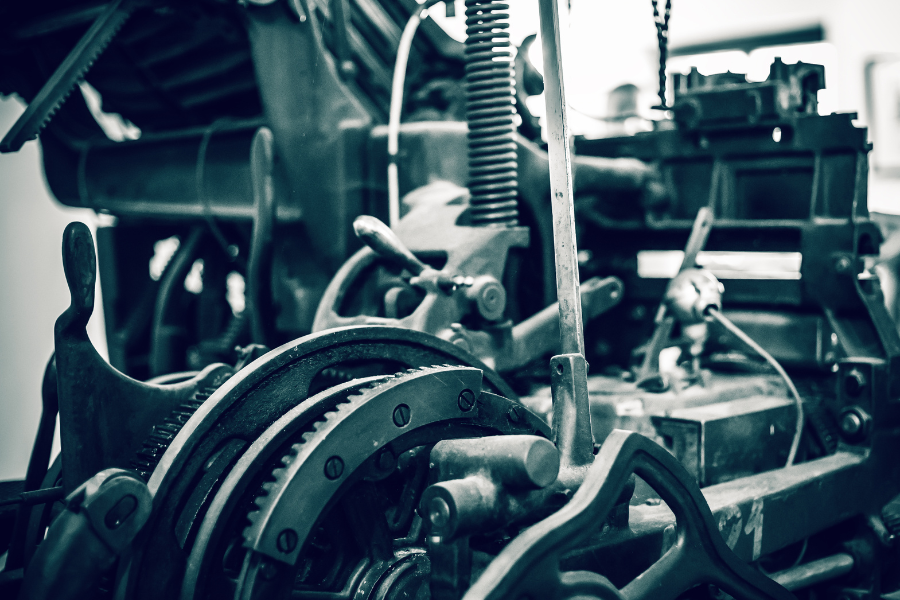

The eccentric presses, also known as crank, work when a flywheel is powered by an electric motor through a belt drive. At this moment, the movement is transmitted through a small and a large toothed wheel, which will be mounted on the eccentric shaft.

In short, these presses use a connecting rod which is implemented through a crankshaft. The flywheel on the top of the machine rotates by electric motor, and when the action is performed, the clutch connects the flywheel shaft to the crankshaft and applies all its force.

Parts of mechanical presses

As previously mentioned, eccentric or crank presses are a type of mechanical press. Since Center die shops we want to explain the parts that make up this type of press:

- Structure: the structure serves as the body of the machine or support, and provides stability to it. This must be solid and resistant, since the force that is applied in the press is of great magnitude.

- connection elements: these elements are the ones that will allow the machine can be assembled and disassembled, as well as its components.

- Nuts and bolts: work like movement transmission elements.

- Fixation and compression of shock absorbers

- Electric motor.

Characteristics of mechanical presses

It should be noted that this type of press has a advantage over the rest, since they are faster, cheaper and more productive. Despite this, they are usually noisier and have greater risk or danger.

Specifically, they have a series of characteristics main:

- fixed stroke length: They usually have a fixed stroke, although it is true that many manufacturers offer eccentric presses with variable stroke length.

- have special sliding movements, as the link movement.

- sliding speed variable.

- The work energy depends on the mass and speed of the flywheel.

- Simplicity of configuration and operation.

- High accuracy.

- cost more economic.

Also, can also be highlighted:

- The ease of handling from the machine to the operator

- The great security at the time of applying or exerting force

- Allows the manufacture of different products with a faster

- Greater precision

Importance of press maintenance

The good maintenance of this type of machines is a fundamental point for its correct operation and to avoid its deterioration. Since Center die shops Here are some recommendations regarding the maintenance of the presses:

- Keep the press in a clean and dry place: to prevent it from rusting

- Carry out monitoring and maintenance of oil in the case of hydraulic presses

- Electrical maintenance: wiring

- Periodically check the pressure

- Frequently grease the spindles, nuts and other elements of friction or friction.

If you want more information on eccentric presses or other types of presses, from Die Center We are at your disposal to resolve any type of doubt about the work presses. contact with us for more information.

Tell us what you think of this article, Rate (FROM 1 TO 5 STARS).